New Locker Room: Safety at our Core!

Russell Reid is the best name in the nonhazardous waste management business for plenty of reasons, but the one we’re most proud of is our emphasis on safety. Since the company’s founding in 1981, Russell Reid has enforced a strict safety policy to ensure the happiness of customer and employee alike. From monthly STOP (Safety, Training, Operation, and Professionalism) meetings, to DriveCams installed on all of our trucks, to a uniform consisting of mandatory personal protective equipment (PPE), we take safety seriously.

Russell Reid is the best name in the nonhazardous waste management business for plenty of reasons, but the one we’re most proud of is our emphasis on safety. Since the company’s founding in 1981, Russell Reid has enforced a strict safety policy to ensure the happiness of customer and employee alike. From monthly STOP (Safety, Training, Operation, and Professionalism) meetings, to DriveCams installed on all of our trucks, to a uniform consisting of mandatory personal protective equipment (PPE), we take safety seriously.

With that in mind, Russell Reid is particularly proud to announce our newly renovated locker room at the Keasbey location. This brand new feature is double the size and steps away from the yard and shop. Each employee has an individual locker to safely store PPE when they’re off the clock and personal belongings during the day. The locker room also boasts a newly installed eye wash station in case of emergency, new lighting and ventilation, and an ADA compliant toilet and lavatory.

When Russell Reid relocated our headquarters to Raritan Center, the corporate services and warehouse spaces were converted into a air-conditioned truck shop that now acts as a new, safe office space for mechanics, a proper storage space, and a facility for new servicing equipment. Each of these features allows Mr. John to be more efficient and work with care and precision.

Every day, Mr. John is working to be the best we can possibly be in the portable sanitation business. But we can’t get there unless we know that our staff are safe and feel secure in their workplace, so they can deliver on what you need most.

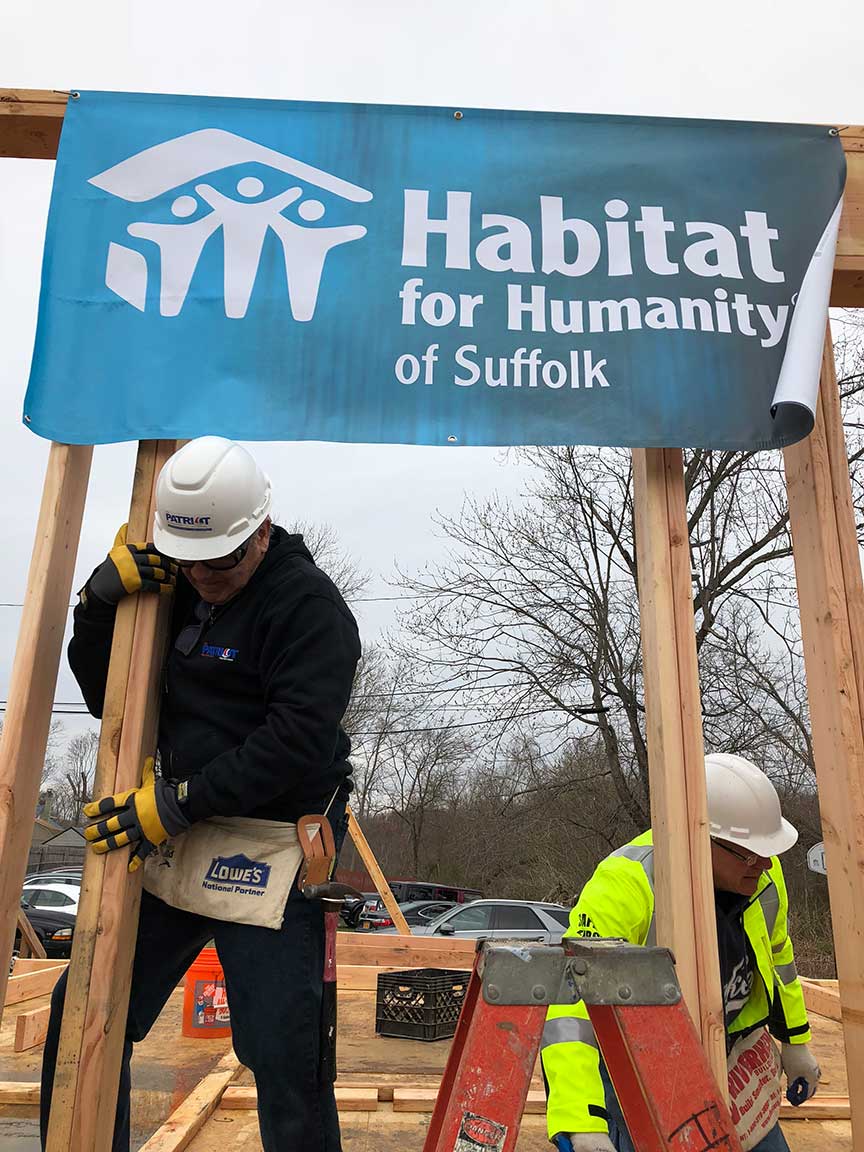

President Gary Weiner Steps On-site with Habitat for Humanity

Kudos to our sister company, Mr. John, for working so closely with Habitat for Humanity over the past few years. This past month, Habitat for Humanity Suffolk County celebrated its 30th anniversary by having CEOs from across Long Island participate in building two homes.

Among the participants was Gary Weiner, President of Mr. John and Russell Reid and active donor to the non-profit. "I thought it was an opportune time to get out and pitch in and actually do the work. Rather than just making a donation in kind, it’s where the rubber hits the road, swing the hammer, bang some nails, and build a house" Weiner said.

There seems to be something special about getting out of the office to participate in real work that makes a difference in the community. Habitat for Humanity has built over 190 homes in the past 30 years, providing affordable homeownership or families in need.

To read the full article on FiOS1News, click here.

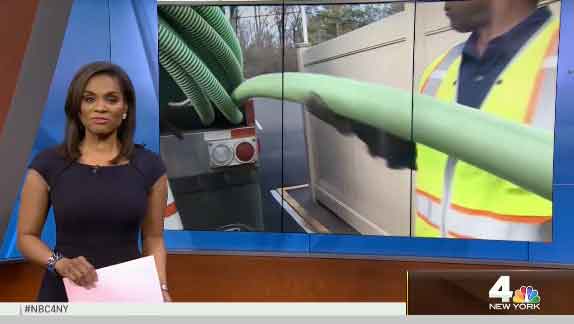

An Unusual Approach to Generating Electricity

In early April, Russell Reid was recognized on NBC New York news as one of the leading waste management companies to be generating electricity in truly innovative way. It turns out leftover fat, oil and grease from restaurant food remains may not be so useless after all.

Leftover restaurant waste turns into a layer of scum that eventually goes down the drain and into grease traps. However, there are only a few companies that pump out the grease and then bring it into a wastewater plant to create electricity. At the Joint Meeting of Essex & Union County Wastewater Treatment Plant, the grease goes into a closed digester tank to make a cleaner methane gas. With this process, we are using less oil, less coal and an overall smaller carbon footprint. This methane gas provides three-fourths of the plant’s electricity, saves about one million dollars per year, and simultaneously helps restaurants become more environmentally sustainable.

Check out the video segment below to watch the full clip:

You can also watch the video on NBC NY here.

Our Fleet is Expanding

We are very excited to announce that our convoy of vehicles will be growing, due to our recent purchase of four fantastic Presvac Vacuum Tank trucks. One of these trucks was showcased at the 2018 Water & Wastewater Equipment, Treatment & Transport Show in Indianapolis this past February. This show, also known by its initials WWETT, is the leading trade show for wastewater and environmental service worldwide.

When Waste Advantage Magazine reached out to our president, Gary Weiner, for a statement, he announced that “these trucks will enhance our operations and make us better able to serve our customers. He also added that “we are constantly upgrading our fleet to offer the best service and reliability for our customers in New York, New Jersey, and greater Philadelphia. We can’t wait to get these trucks on the road.”

These new vehicles are completely state of the art and will begin to streamline our efforts to provide our customers with the best service possible.

We would also like to offer our gratitude to the New Jersey companies who helped supply us with these trucks. The models, themselves, were supplied by Hunter Jersey Peterbilt in nearby Clarksburg, while the Presvac units were supplied by Vacuum Sales, Inc. in Lindenwold.

You will be seeing these new trucks out on the road very soon! Be on the lookout for them!

For the full story, see here:

An Early Decision to Invest in New Technology Reaps Long-term Benefits

Early on we made the decision to invest in a technology, which would enable our company to grow. The AMCS Platform did just that and continues to give our organization flexibility and scalability.

The AMCS Enterprise is more than an ERP solution, it is the foundation to automating a business. Through it’s platform, it covers the full waste management process. With end-to-end integrated solutions it aids in the management of your assets and resources, standardise your processes and legal compliance.

Rob Suessmann, Logistic Manager; "The most exciting thing for us was when AMCS introduced a mobile solution that integrates with our Enterprise Management solution. In the past, everything was a manual process. Deploying mobile devices to our field service group was really transformative. We are able to track the beginning of the order at the dispatch department and process it all the way through to the driver’s mobile app and then back to the home office. For us, knowing where the trucks are at any given time has allowed us to handle on-call and emergency status work. By pinpointing the location of the vehicles and what their capabilities are, we can delegate the work more efficiently to the appropriate resource and therefore making our response to our customers much better."

Not only are we gaining insights into our business performance, we are also streamlining process and increasing productivity through improved daily communication from the office to the field. With all of this, we have been working towards eliminating paper entirely, saving both costs and efficiencies.

To read the full case study, click here.

We Are a Culture of Safety

Since 1964, we have provided non-hazardous wastewater management solutions as well as portable restroom services throughout New Jersey, New York, Pennsylvania and beyond.

“Gary Weiner, President, committed Russell Reid to a culture of safety which involved significant financial resources as well as time and commitment of the management team, to implement throughout the entire organization.” - Suzie Stark, Charter Partners

Throughout the company, yearly average work-related injuries have reduced from 103 to remaining in the low 30’s due to safety initiatives that have been put in place.

We have experienced consistently decreasing ‘Workers Compensation Experience Modification’ numbers which result in healthcare ‘premium’ discounts.

For the full story, read here.

Driving Growth

RUSSELL REID’S DIVERSE SERVICES ARE SUPPORTED BY THE STRENGTH OF ITS FLEET

Over the last 35 years, Russell Reid has grown from a small septic pumping company into one of the biggest waste hauling and disposal companies in the northeastern United States. The growth formula was relatively simple: Provide great customer service. Period.

But at Russell Reid in Edison, New Jersey, great customer service takes many forms — it’s much more nuanced than just showing up on time and finishing projects on schedule. It also means providing a diverse array of services to give customers the convenience of one-stop shopping, and investing in the best equipment and technology to maximize productivity and minimize work stoppages caused by breakdowns, says Devin Dam, the company’s outside sales manager.

“It all sort of happened organically,” Dam says. “When you pump septic tanks, for instance, you encounter opportunities to use jetting equipment. And when you clean sewer pipes, you realize you need cameras for post-cleaning inspections. You just naturally take on different kinds of work, or customers suggest that you start a new line of service. It’s all about customer service.”

The Right Trucks

Russell Reid was established in 1943. Morton Weiner, the founder and owner of Mr. John Company, a portable restroom outfit, acquired the company in 1981, ushering in a new era of growth and diversification. Today, Russell Reid’s primary focus is nonhazardous liquid- and solid-waste hauling and disposal. The company also performs infrastructure maintenance, such as cleaning and inspecting sewer systems, pump stations, digesters and lagoons.

Of course, providing all those services requires a lot of equipment. Russell Reid’s fleet includes about 70 vacuum trucks, ranging in size from 3,500- to 7,000-gallon capacity; two CCTV inspection trucks; and five Vac-Con combination jet/vac trucks equipped with hydroexcavating packages. All have played an important role in the company’s growth. “Investing in the most reliable equipment allows us to do jobs more effectively and without costly breakdowns,” Dam says. “Owning better equipment than our competitors have been critical to our growth.”

The Vac-Con units are spec’d for maximum productivity. Each one features an 11-cubic-yard (2,200-gallon) steel debris tank; a positive displacement blower that generates vacuum power of 4,500 cfm; 1,000-gallon water tanks; hydraulically operated, front-mounted hose reel; a telescoping boom; a hydraulically operated scissor-lift dump system; and a fully opening rear hinged door. Four of the trucks are equipped with a water pump that delivers pressure and flow up to 3,000 psi at 50 GPM through a 600-foot-long, 3/4-inch-diameter hose, while the other truck’s pump produces 3,000 psi at 80 GPM via a 1-inch hose.

“The lift-and-tilt feature is invaluable — we can’t do the work we do without it,” Dam says of the off-loading system, which lifts the debris tank high enough to dump into roll-off containers on job sites and keeps the trucks working instead of leaving to make frequent disposal runs. The tank also tilts 75 degrees, which lets gravity do most of the heavy lifting when it’s time to empty the tank. Moreover, an internal, high-pressure wash system powered by the truck’s water pump washes out any debris that’s left clinging to the tank.

“We’re usually dealing with thick, solid material, so the only way to get it out of the tank is to use gravity,” he explains. “In addition, most of the places we dump are not set up to take materials through a hose — we might be set up to dump onto a concrete pad with a sloped floor or into a landfill or into a roll-off container. We have to be prepared for all those situations, and the high-dump and tilt features give us the flexibility to do that.”

The company spec’d positive displacement blowers instead of three-stage fans for the Vac-Cons because they often must suck thick, heavy solids at long distances from facilities such as pump stations and catch basins or from heavily impacted grease traps, where the grease is solidified to the point that it’s almost like concrete. “Traditional vac trucks can’t remove those kinds of materials,” Dam says. “We need a lot of power because we’re often pulling at significant distances and depths.”

The Vac-Cons are workhorses used for everything from commercial and industrial work (cleaning process tanks in plants and factories, for example) to municipal cleaning. “We need to be able to cover the whole gamut because we serve so many different kinds of customers,” Dam says.

On The Job

One of the toughest jobs Russell Reid crews tackle is cleaning wastewater treatment plant infrastructure — items such as digesters, aeration tanks and clarifiers. That typically requires the Vac-Cons to move thousands of gallons of liquid waste and hundreds of yards of solid waste. “You definitely need a truck with a lot of power that can move a lot of air and run long and hard — sometimes eight to 10 hours at a pop,” Dam points out. “That’s where these trucks really shine.

“The Vac-Cons can suck up anything, from water to bowling balls,” he adds. “When we show up with our Vac-Cons, our customers know we won’t have any problems sucking up liquids or solid waste. It’s one of the bestselling points we can offer, especially if our competitors are running pump trucks that aren’t set up to handle things like heavy solids at great distances and depths.”

Reliable equipment also plays a role in customer service because it helps ensure that jobs get finished in a timely fashion, which minimizes disruptions for clients. It also helps boost the bottom line, Dam points out. “We call breakdowns a ‘false start,’” he explains. “You’re essentially bleeding out because you’re paying for the labor and fuel, while at the same time you’re paying to fix the truck or machine — and the whole time, you’re unable to bill the customer. All you’re doing is paying out money without getting paid.”

Keeping a lid on expenses also helps out customers, which is why Russell Reid has a team of employees, led by an environmental compliance manager, that’s dedicated to finding strategically located waste disposal sites that minimize driving times and distances for disposal runs. Liquid wastes — such as sewage, industrial process water, sludge and oily wastewater — typically go to treatment centers, while solids get taken to landfills or other facilities. “If we can load it on a truck and it’s nonhazardous in nature, we can find a home for it,” Dam says. “We always use the most inexpensive and closest disposal facility possible.”

Better Options

The company outfitted the Vac-Cons with hydroexcavating packages to add another convenience for customers. While hydroexcavating is not a huge part of the company’s overall business volume, Dam says it’s growing — and it’s great to have the capability when customers need it. It also provides safer options for employees when cleaning items like lift stations or tanks because the hydroexcavating wand can operate at a lower pressure (1,500 psi at a variable flow rate) than the truck’s water jetter.

“That makes it easier to handle,” Dam says. “And sometimes, if we’re cleaning old pipe, for instance, we don’t want to go in with the highest possible pressure and flow because it might break the pipe. The same is true for things such as sewage pumps, which have delicate parts. The hydroexcavating gun allows us to back down the pressure and flow to a safer level.”

In-the-field technology for employees also factors into better customer service. For example, sophisticated business management systems and software enable customers to perform functions such as viewing and paying bills online and placing orders via email. “All paperwork — from work orders to disposal manifests — is scanned and stored digitally,” Dam points out. “When a customer requests documents, we can pull them and email them.”

Furthermore, field technicians are equipped with hand-held computer tablets that essentially eliminate the need for paperwork. The tablets can also track jobs, take photos in the field (which can be posted to customers’ accounts in real time) and allow technicians to remain digitally connected even if they’re out of range of the company’s network, Dam says.

“We’re dealing with more sophisticated customers than in the past,” he continues. “Most of our customers are used to using digitally based systems and the internet. Even here in the waste world, we have to keep up with those kinds of technologies and bring our industry online along with everyone else. People assume that waste haulers aren’t going to be very tech savvy, so we go out of our way to be just that.

“Anyone can show up with a vacuum truck to clean something out — that’s not the hard part,” he concludes. “But being a step above our competitors in terms of customer service is what really sets us apart in this industry.”

Russell Reid Acquires Pumping and Hauling Portion of Aqua Resources

Aqua sold the division, which is located in Souderton, Pa., to focus on its core operations of expertly providing water and wastewater services in the communities it serves. To offer continuity to its customers and employees, Aqua selected Russell Reid, whose core values are closely aligned with their own.

The pumping and hauling division supplies services identical to Russell Reid’s—bulk hauling for municipal treatment works, non-hazardous industrial wastewater transportation and disposal, septic tank and grease trap pumping and lift station and ejector pit cleaning.

The acquisition includes a leased building with office, yard and shop; nine tractors, eight vacuum trailers, 12 vacuum straight trucks, one Jet Vac, one high-pressure water jet and miscellaneous other equipment. The business is staffed with field service technicians, mechanics and office staff, including a dispatcher, customer service representative and assistant administrator.

All the acquired vehicles will be rebranded with the Russell Reid name and logos. According to Russell Reid President Gary M. Weiner, “We are pleased that the vast majority of Aqua’s dedicated and professional staff have become Russell Reid employees as well. The goal is to smoothly integrate their operations into ours and establish Souderton, Pa., as the newest service center for Russell Reid and Mr. John. In addition, to acquiring a solid book of commercial and industrial business, part of the acquisition agreement includes ongoing sludge hauling and disposal services to Aqua facilities.”

Aqua Resources’ President Anthony J. Donatoni stated, “We are pleased with the outcome of this transaction and for our employees as well. Russell Reid will continue to be a leader in the wastewater hauling business and we wish them much success.” With a service area encompassing eastern Pennsylvania, parts of New Jersey and northern Delaware, “This acquisition immediately and significantly enhances the landscape of our tri-state service area and further demonstrates our ability to expand into new markets and achieve sustainable growth,” said Weiner.

About Russell Reid:

Russell Reid has been providing wastewater management services to commercial, municipal, industrial and residential customers since 1943. The company serves New Jersey, greater New York, eastern PA and DE from seven strategic locations.

For more information, contact Russell Reid at 800-356-4468 or visit the company’s web site at www.russellreid.com.

About AQUA:

AQUA is one of the largest U.S. – based, publicly traded water utilities and serves nearly 3 million people in Pennsylvania, Ohio, North Carolina, Illinois, Texas, New Jersey, Indiana and Virginia. Aqua America is listed on the New York Stock Exchange under the ticker symbol WTR. Visit AquaAmerica.com for more information.

Russell Reid and Mr. John now offer electronic invoicing and payments online!

Mr. John and Russell Reid are pleased to announce that we now offer electronic invoicing and payments online! We are confident that these new features will be beneficial to both our customers and our employees.

Traditional invoicing by mail can lead to delays or even loss. With electronic invoicing, documents are sent immediately and recipients can review or forward with just a few mouse clicks. We strongly believe that electronic invoicing will provide a more positive experience all around. Not only is the process streamlined and more reliable but it saves resources by reducing the consumption of paper, energy, and time.

Simultaneously, we are proud to introduce our online payment platform that simplifies payment processing while ensuring customer information is safe and secure. Available 24 hours a day, 365 days per year this new feature is ready to accept payments when you are ready to make them. Customers can make a payment, view their account history, change account settings and more. “Being in the service business we are constantly looking to enhance the experience our customers receive; we’re confident that our new e-billing and online payment options will provide another level of service our customers will appreciate” said Steve Stefanski, Vice President of Finance.

Josiane, a Mr. John electronic invoice and on-line bill pay customer, recently stated “The website for online bill-pay is definitely a convenience for our company. Signing up was straight forward and everything was accurate...It is also a lot quicker to pay our bill this way, since I don't need to write out a check and mail it back…I definitely appreciate the efficiency of the e-billing system and all of your help to set it up for our company. Thank you!”

The company looks forward to serving its customers with new “easy to use” features. Think faster, easier, more reliable and secure! If you have any questions about our e-invoicing or making payments online please contact our billing department at 732-692-2487 or by e-mail at billinghelpdesk@www.russellreid.com or billinghelpdesk@mrjohn.com.

To sign up for e-invoicing click here. To sign up for online payments click here.

Russell Reid and Mr. John Announce Their New Service Center Just A Few Miles Outside Center City Philadelphia!

Mr. John and Russell Reid are proud to announce the opening of our new service center on Route 41 in Deptford, NJ. This new state of art facility is just a few short miles from Center City Philadelphia. Mr. John and Russell Reid have provided temporary restroom and wastewater management services in the Philadelphia area since 1967. We are confident our new service center will help us in our continued quest to provide our Philadelphia customers with the best service experience our industry has to offer.

Mr. John and Russell Reid offer the following products and services in the Philadelphia, PA market:

• Temporary Restroom Equipment/Service: Our huge inventory includes a wide range of facilities designed to go where the work is, including standard temporary restrooms, porta johns, high rise units, fresh water systems for field office trailers, hand sinks, restroom trailers/containers, and related accessories. We also offer several temporary restroom options forspecial events ranging from the “ordinary to the extraordinary”.

• Responsible Wastewater Management: We provide vacuum truck services and bulk hauling, combination jet vac, video pipeline inspection, bulk liquid storage, confined space entry and more.

Mr. John and Russell Reid are committed to providing the best service possible and are continually improving our services. Furthermore, we've recently made some changes to improve our operations which include:

• Our customers can now pay their invoices online, receive their invoices via e-mail, as well as submit service inquiries and billing questions via our newly improved web sites.

• Our Service Technicians are now PSAI certified and have undergone industry training through the Portable Sanitation Association International.

• Our new low emission vehicles are equipped with GPS systems to track your service in real time.

We encourage our current and potential customers to tap in to our 50 years of experience and well established industry relationships to simplify their Philadelphia temporary restroom and wastewater management needs. Our project managers, technicians and support staff are ready to assist with project management, consultations or site assessments to help our clients meet their goals.

For Mr. John services, please feel free to contact us at any time via our toll free number at (800) 628-8955, via e-mail at customercare@mrjohn.com and/or via live chat on our website.

For Russell Reid services, please feel free to contact us at any time via our toll free number at (800) 356-4468, via e-mail at customercare@www.russellreid.com and/or via live chat on our website.