Septic Pumping During COVID-19

Septic pumping is one of the most fundamental things that you can do to keep your septic system functioning properly. With residents spending more time at home to abide by local COVID-19 shelter-in place orders, it’s important to be conscious of the increased use of your residential septic system. Household members being home more contributes to the production of more waste water along with increased home activities that impact your septic system.

As you increase use of your septic system, you’ll need to increase the frequency in which your septic system is serviced. The good news is that waste management services have been deemed essential by Federal and State governments and septic service can be completed without contact, abiding by social distancing practices.

As a homeowner, proper septic management practices are essential to help keep your septic system in peak operating condition. Here are some key things you should understand about your septic system and take into consideration during these high use times.

WHAT IS A SEPTIC SYSTEM?

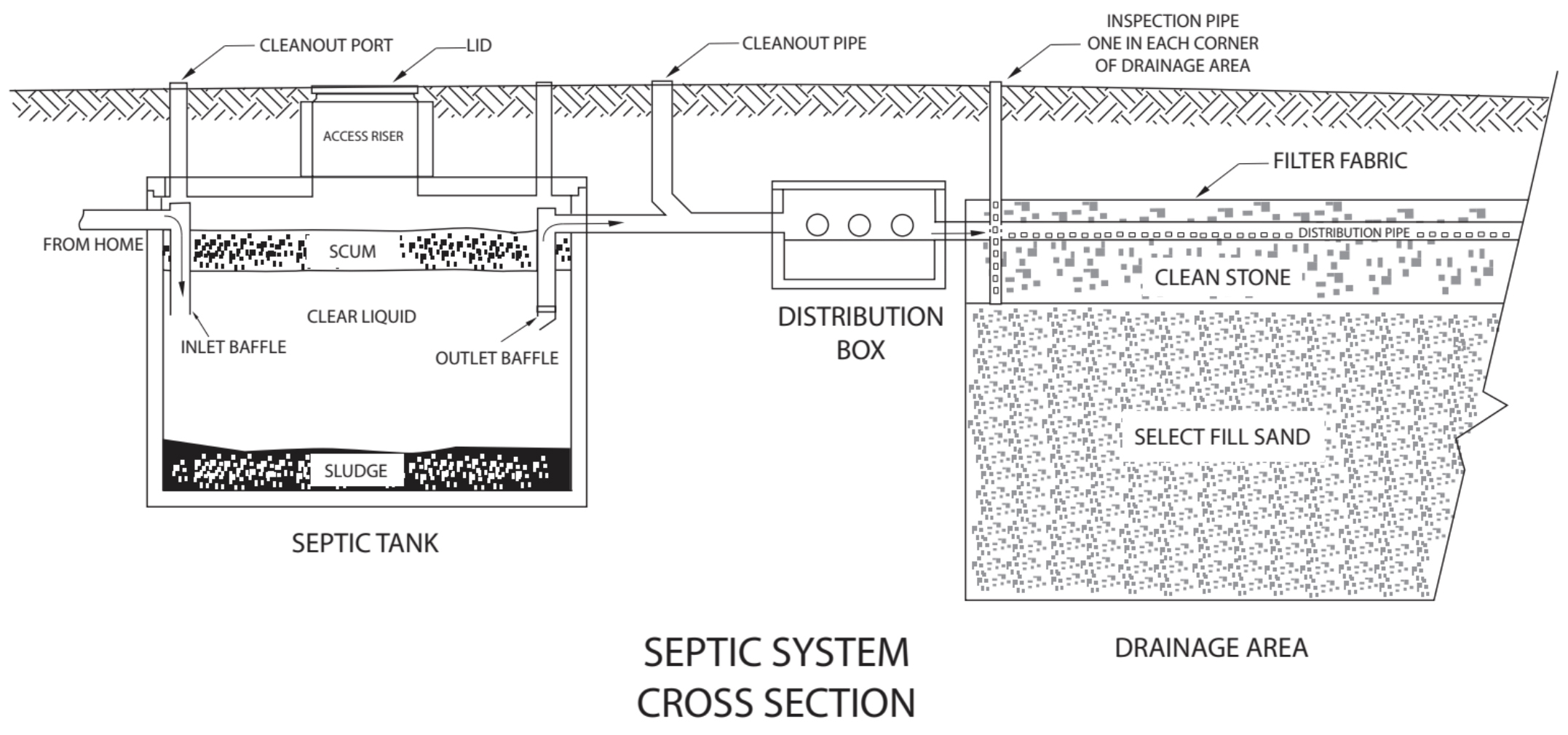

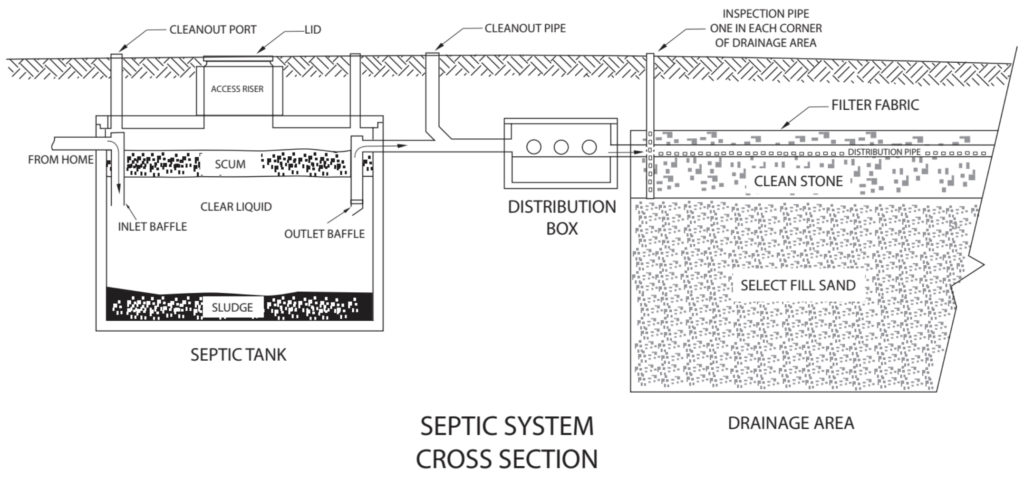

A subsurface sewage disposal system, commonly known as a septic system, consists of two main components: the septic tank, also known as the treatment tank, and the drainage area, often referred to as the leach field. The system also includes a main sewer line, which connects all plumbing fixtures to the septic tank, as well as a distribution box that connects

the septic tank to the drainage field. The septic tank is buried approximately 10 to 15 feet from the dwelling.

The purpose of a septic system is to treat and dispose of wastewater generated by the occupants. When properly installed and adequately maintained, septic systems are more

economical than sanitary sewers and just as efficient.

HOW YOUR SEPTIC SYSTEM WORKS

All wastewater generated from the dwelling enters the septic tank where primary treatment occurs. Anaerobic bacteria (bacteria found in environments without oxygen) thrive in the septic tank where they organically break down solids, creating sludge. Lighter materials such as grease and soap float to the top of the tank and form a layer called scum. This simple settling process allows virtually all of the wastewater (effluent) to flow out of the septic tank free of grease, soap and solids. It is important to remember that the septic tank inlet and outlet pipes are near the top of the tank. Thus, the septic tank always appears full.

The relatively clear wastewater exits the septic tank outlet and flows into the distribution box (D-box). The purpose of the distribution box is to evenly distribute the wastewater flow throughout the drainage field. Once in the drainage field, the wastewater passes through perforated lateral pipes, a layer of crushed stone and finally through several feet of unsaturated soil. As the treated wastewater travels through the soil, bacteria die off and the water is purified.

SEPTIC SYSTEM MAINTENANCE

Periodic maintenance is the key to extending the life of your septic system and preventing costly repairs. When the combined depth of the sludge and scum layers equal one-third of the septic tank capacity, the tank should be pumped. The accumulated sludge and scum from the septic tanks should be pumped a minimum of every three years, or more frequently if your household consists of four people or more.

A general rule for locating your septic tank is to probe with a shale bar or steel rod 10 to 15 feet from where the main sewer line exits the foundation of the dwelling. Patience and determination will help you locate the outer edges of the tank. Once located, dig a hole toward the center to expose the main cover only, usually 24" in diameter.

Russell Reid, A United Site Services Company offers septic pumping services in the greater Tri-State area. Schedule septic pumping services today or call 1.800.356.4468 to speak with a customer service representative today!

Celebrate the 4th of July with Russell Reid!

Happy 242nd, Uncle Sam! Nothing says Summer like the 4th of July – so put on your red, white, and blue and get ready to celebrate America with Russell Reid! All over the country, Americans will be covered in stars and stripes, barbecuing and watching fireworks. We want to be there to ensure that your patriotic party goes smoothly.

As you spangle your house with flags and banners, Russell Reid will provide you with the services you need to make sure everything runs just right. Your septic system might not be the first of your worries when planning a 4th of July Party, but Russell Reid is here to help.

Make sure to remind your guests who are using your bathrooms not to flush anything down the toilet that doesn’t easily decompose. This includes the small stuff too, like matches, tampons, cigarette butts, wipes, and diapers.

While preparing for your party, try to limit your water use as to not overload the tank with liquids to drain. You can be prudent by sweeping your driveway and sidewalks instead of hosing them down, limiting shower time, and perhaps taking a look at our sister company, United Site Services, to rent some portable toilets instead of having everyone flushing all night long!

If it’s time for a pump before the 4th, give us a call! No one wants a septic emergency on their big night. Russell Reid is here to help you celebrate the right way. Kick back, watch the fireworks, and have some bbq – in the spirit of the 4th of July!

Place your order here!

Planning a Party this Summer? Russell Reid Can Help Ensure Things Go Smoothly!

Even though the weather in the Tri-State area hasn’t been picture perfect this spring, Mid-May means that we at Mr. John and Russell Reid have one thing on our minds: Summer. Once these clouds clear up, some sunshine calls for celebration. May and June are the perfect time for outdoor summer parties, and while you and your guests are celebrating Memorial Day, a graduation, or a just indulging in a reason to have some fun, we’re your one-stop shop for the party details that are a little less fun to plan.

While you choose your color scheme and decor, Russell Reid will provide you with the services you need to make sure everything runs smoothly. You may not choose to make small talk about it with the guests, but the truth is that everyone needs a place to go.

Does your home run on a septic system? If you’re suddenly expecting all of your daughter’s high school graduating class over for a party, the last thing anyone would want to handle on their special day is a septic emergency. Russell Reid offers pumping service to ensure your system is up to capacity for the grads!

Should you choose to close the doors to your home’s bathrooms, our sister company Mr. John has a wide variety of portable toilets and deluxe trailers for you to provide for your guests instead.

Whatever your reason for celebration, the Russell Reid Company wants to be there to provide you with reliable, efficient, and clean service. Let’s kick off summer together!

Two Signs It's Time to Clean Your Grease Trap

If you’re a restaurant owner, you know the grease trap is one of the most important parts of your commercial kitchen. Grease traps catch the fats and oils that come off of plates to prevent the pipes in your building from being clogged. It’s also the toughest reservoir to manage, as it is hard to know the level of waste unless the trap is disassembled. Regardless, when the sludge reaches a 25% occupancy of the tank, you are required by law to pump out the trap.

It can be a nightmare to clean out a grease trap yourself— consider hiring a reputable waste management company to pump out the trap quickly and efficiently. Russell Reid is a reputable choice, view a list of their services here.

So, how do you know when it is the right time to call the pros? We have all the warning signs below to keep you on your toes.

Do you smell a scent that just won’t go away?

All the leftover food waste sitting in the grease trap is going to smell after it’s been sitting for quite some time. Any bad odor coming from the grease trap area is a dead giveaway it's time to tend to the grease trap quickly.

Is there a buildup of water coming through your sinks?

Grease and water don’t sit too nicely together— when grease builds up, it creates a barrier that stops water from easily draining through. If you’re seeing this don’t wait too long— a significant enough drainage buildup can hinder your dishwashers and other equipment from doing its job.

In other words, pay extra attention to your grease trap. Tune into these two problem areas and try to have a technician in once every 90 days to avoid any issues from interfering with your kitchen.

We Are a Culture of Safety

Since 1964, we have provided non-hazardous wastewater management solutions as well as portable restroom services throughout New Jersey, New York, Pennsylvania and beyond.

“Gary Weiner, President, committed Russell Reid to a culture of safety which involved significant financial resources as well as time and commitment of the management team, to implement throughout the entire organization.” - Suzie Stark, Charter Partners

Throughout the company, yearly average work-related injuries have reduced from 103 to remaining in the low 30’s due to safety initiatives that have been put in place.

We have experienced consistently decreasing ‘Workers Compensation Experience Modification’ numbers which result in healthcare ‘premium’ discounts.

For the full story, read here.

Driving Growth

RUSSELL REID’S DIVERSE SERVICES ARE SUPPORTED BY THE STRENGTH OF ITS FLEET

Over the last 35 years, Russell Reid has grown from a small septic pumping company into one of the biggest waste hauling and disposal companies in the northeastern United States. The growth formula was relatively simple: Provide great customer service. Period.

But at Russell Reid in Edison, New Jersey, great customer service takes many forms — it’s much more nuanced than just showing up on time and finishing projects on schedule. It also means providing a diverse array of services to give customers the convenience of one-stop shopping, and investing in the best equipment and technology to maximize productivity and minimize work stoppages caused by breakdowns, says Devin Dam, the company’s outside sales manager.

“It all sort of happened organically,” Dam says. “When you pump septic tanks, for instance, you encounter opportunities to use jetting equipment. And when you clean sewer pipes, you realize you need cameras for post-cleaning inspections. You just naturally take on different kinds of work, or customers suggest that you start a new line of service. It’s all about customer service.”

The Right Trucks

Russell Reid was established in 1943. Morton Weiner, the founder and owner of Mr. John Company, a portable restroom outfit, acquired the company in 1981, ushering in a new era of growth and diversification. Today, Russell Reid’s primary focus is nonhazardous liquid- and solid-waste hauling and disposal. The company also performs infrastructure maintenance, such as cleaning and inspecting sewer systems, pump stations, digesters and lagoons.

Of course, providing all those services requires a lot of equipment. Russell Reid’s fleet includes about 70 vacuum trucks, ranging in size from 3,500- to 7,000-gallon capacity; two CCTV inspection trucks; and five Vac-Con combination jet/vac trucks equipped with hydroexcavating packages. All have played an important role in the company’s growth. “Investing in the most reliable equipment allows us to do jobs more effectively and without costly breakdowns,” Dam says. “Owning better equipment than our competitors have been critical to our growth.”

The Vac-Con units are spec’d for maximum productivity. Each one features an 11-cubic-yard (2,200-gallon) steel debris tank; a positive displacement blower that generates vacuum power of 4,500 cfm; 1,000-gallon water tanks; hydraulically operated, front-mounted hose reel; a telescoping boom; a hydraulically operated scissor-lift dump system; and a fully opening rear hinged door. Four of the trucks are equipped with a water pump that delivers pressure and flow up to 3,000 psi at 50 GPM through a 600-foot-long, 3/4-inch-diameter hose, while the other truck’s pump produces 3,000 psi at 80 GPM via a 1-inch hose.

“The lift-and-tilt feature is invaluable — we can’t do the work we do without it,” Dam says of the off-loading system, which lifts the debris tank high enough to dump into roll-off containers on job sites and keeps the trucks working instead of leaving to make frequent disposal runs. The tank also tilts 75 degrees, which lets gravity do most of the heavy lifting when it’s time to empty the tank. Moreover, an internal, high-pressure wash system powered by the truck’s water pump washes out any debris that’s left clinging to the tank.

“We’re usually dealing with thick, solid material, so the only way to get it out of the tank is to use gravity,” he explains. “In addition, most of the places we dump are not set up to take materials through a hose — we might be set up to dump onto a concrete pad with a sloped floor or into a landfill or into a roll-off container. We have to be prepared for all those situations, and the high-dump and tilt features give us the flexibility to do that.”

The company spec’d positive displacement blowers instead of three-stage fans for the Vac-Cons because they often must suck thick, heavy solids at long distances from facilities such as pump stations and catch basins or from heavily impacted grease traps, where the grease is solidified to the point that it’s almost like concrete. “Traditional vac trucks can’t remove those kinds of materials,” Dam says. “We need a lot of power because we’re often pulling at significant distances and depths.”

The Vac-Cons are workhorses used for everything from commercial and industrial work (cleaning process tanks in plants and factories, for example) to municipal cleaning. “We need to be able to cover the whole gamut because we serve so many different kinds of customers,” Dam says.

On The Job

One of the toughest jobs Russell Reid crews tackle is cleaning wastewater treatment plant infrastructure — items such as digesters, aeration tanks and clarifiers. That typically requires the Vac-Cons to move thousands of gallons of liquid waste and hundreds of yards of solid waste. “You definitely need a truck with a lot of power that can move a lot of air and run long and hard — sometimes eight to 10 hours at a pop,” Dam points out. “That’s where these trucks really shine.

“The Vac-Cons can suck up anything, from water to bowling balls,” he adds. “When we show up with our Vac-Cons, our customers know we won’t have any problems sucking up liquids or solid waste. It’s one of the bestselling points we can offer, especially if our competitors are running pump trucks that aren’t set up to handle things like heavy solids at great distances and depths.”

Reliable equipment also plays a role in customer service because it helps ensure that jobs get finished in a timely fashion, which minimizes disruptions for clients. It also helps boost the bottom line, Dam points out. “We call breakdowns a ‘false start,’” he explains. “You’re essentially bleeding out because you’re paying for the labor and fuel, while at the same time you’re paying to fix the truck or machine — and the whole time, you’re unable to bill the customer. All you’re doing is paying out money without getting paid.”

Keeping a lid on expenses also helps out customers, which is why Russell Reid has a team of employees, led by an environmental compliance manager, that’s dedicated to finding strategically located waste disposal sites that minimize driving times and distances for disposal runs. Liquid wastes — such as sewage, industrial process water, sludge and oily wastewater — typically go to treatment centers, while solids get taken to landfills or other facilities. “If we can load it on a truck and it’s nonhazardous in nature, we can find a home for it,” Dam says. “We always use the most inexpensive and closest disposal facility possible.”

Better Options

The company outfitted the Vac-Cons with hydroexcavating packages to add another convenience for customers. While hydroexcavating is not a huge part of the company’s overall business volume, Dam says it’s growing — and it’s great to have the capability when customers need it. It also provides safer options for employees when cleaning items like lift stations or tanks because the hydroexcavating wand can operate at a lower pressure (1,500 psi at a variable flow rate) than the truck’s water jetter.

“That makes it easier to handle,” Dam says. “And sometimes, if we’re cleaning old pipe, for instance, we don’t want to go in with the highest possible pressure and flow because it might break the pipe. The same is true for things such as sewage pumps, which have delicate parts. The hydroexcavating gun allows us to back down the pressure and flow to a safer level.”

In-the-field technology for employees also factors into better customer service. For example, sophisticated business management systems and software enable customers to perform functions such as viewing and paying bills online and placing orders via email. “All paperwork — from work orders to disposal manifests — is scanned and stored digitally,” Dam points out. “When a customer requests documents, we can pull them and email them.”

Furthermore, field technicians are equipped with hand-held computer tablets that essentially eliminate the need for paperwork. The tablets can also track jobs, take photos in the field (which can be posted to customers’ accounts in real time) and allow technicians to remain digitally connected even if they’re out of range of the company’s network, Dam says.

“We’re dealing with more sophisticated customers than in the past,” he continues. “Most of our customers are used to using digitally based systems and the internet. Even here in the waste world, we have to keep up with those kinds of technologies and bring our industry online along with everyone else. People assume that waste haulers aren’t going to be very tech savvy, so we go out of our way to be just that.

“Anyone can show up with a vacuum truck to clean something out — that’s not the hard part,” he concludes. “But being a step above our competitors in terms of customer service is what really sets us apart in this industry.”

Russell Reid Takes on the Manasquan River Intake Pump Station Sediment Removal Project

In August of 2013, Russell Reid executed the Manasquan River Pump Station Sediment Removal Project in Wall, New Jersey. We dedicated a team of six (6) Field Service Technicians, along with six (6) Service Vehicles to complete the project, which took a total of four (4) days to complete (August 20th through August 23rd).

The Manasquan River Pump Station Sediment Removal Project required us to remove river sediment from the Manasquan River intake pumping station. We used two (2) of our Combination Jet-Vac trucks, two (2) Vacuum Containers, along with Confined Space Entry to execute the service. The sediment that was removed from the intake station was then managed on site in a contained area designated by the customer

Russell Reid is committed to providing the best customer service experience our industry has to offer. In order to achieve this goal, we created a detailed project plan for our Field Service Technicians and Project Management Team prior to the start of the project. The first step was to perform a site visit which allowed us to figure out the most efficient way to complete the work. After reviewing the scope of work and the lay of the land, we decided to load-in and set up all the equipment we would need to complete the job before the work actually started. This process included leaving some of the trucks onsite, having a truck available at all times to refuel the onsite equipment and having all the equipment (hose, lighting, rope, confined space entry gear, etc.) readily available to perform the service as efficiently as possible. This initial planning allowed Russell Reid to perform the work in a well-organized, efficient manner.

Despite our extensive preparation, our Service Technicians did face some obstacles as the job progressed. One of the obstacles involved water leaking into the tank under the tarps which resulted in filling up the Vacuum Containers with more liquid than solids. In order to resolve this issue, the customer had to reset the pump to evacuate the water coming in from under the tarps. In addition, Russell Reid cleaned the solids from the wall which allowed the water to run through underneath to where the hydraulic pump was set (which was deeper than the floor we were cleaning), allowing the pump to remove the water. We also evacuated piles of sand which slowed down the process of removing the sediment. Not only is vacuuming sand more time consuming, but the distance in which we were vacuuming the sediment out was also very extensive (over 200 feet).

A considerable amount of time and effort was put into the project and the Russell Reid Company was pleased with the overall outcome. Regardless of the hiccups the Field Service Technicians encountered, the technicians were well prepared and were able to overcome the obstacles. Everyone involved in the project contributed to the company’s success and our customer was extremely impressed in our ability to prepare for the job, execute our plan, and perform the service in a timely manner.

The Manasquan River Pump Station Sediment Removal Project is a testament to the way the Russell Reid Company continuously provides the best service in the industry. We take pride in our ability to get the work done the right way and the way we conduct ourselves as a company. Our goal is to maintain our good customer relationships and continue to build more in the future.

Russell Reid is available for serve our customers 24 Hours: 7 Days a Week. Please feel free to reference our website or call us at (800) 356-4468.

Contech Construction Products Inc. Names Russell Reid a Preferred Maintenance Service Provider

Contech Construction Products is a company that has offered civil engineering materials for projects such as bridges, drainage improvement, erosion control, storm water filtration, roadways, and retaining walls since 1986. Contech’s line of storm water filtration systems prevents debris and pollutants from entering ground and surface water. This allows any site to function efficiently while complying with State and Federal environmental regulations.

Contech offers different types of storm water management options, such as the CDS, Vortech, and StormFilter systems. Contech suggests that these systems be inspected at a minimum two times a year. Additional inspections may be necessary for filtration systems in locations where winter sanding, equipment wash downs, or where high amounts of refuse accumulate. These conditions may cause a higher volume of buildup and debris in the filters. When cleaning is necessary, a technician will need to enter the storm system, empty and replace the old filters and remove any additional sediment using a vacuum truck.

Contech’s products require specific equipment and skills to inspect and maintain. To ensure the quality and functionality of their equipment Contech Construction Products has selected the Russell Reid Company as a Preferred Service Maintenance Provider for the Tri-State area. Our company’s specialized service background makes us a perfect fit for servicing CDS, Vortech and StormFilter systems. We operate a fleet of specialized Sewer Cleaning Vacuum Trucks engineered to clean and maintain sewer and storm water collection systems. Our highly trained service technicians are OSHA (Occupational Safety and Health Act) certified to perform Confined Space Entry. The Russell Reid Company takes pride in performing work with the highest safety standards in the industry.

“Contech Construction Products Inc. has chosen Russell Reid to become our Preferred Service Provider for New Jersey on account of their industry knowledge and willingness to step out into the forefront of the Storm water Maintenance Industry,” says John R. Brown Jr., Contech Maintenance Director in the Eastern United States. He adds “We take comfort in knowing our Storm Filter owners/managers will receive the best service and knowledge the industry has to offer.”

Russell Reid is proud to be named as a Contech Preferred Maintenance Service Provider. We look forward to providing all Contech Construction Product customers with exceptional service for many years to come.

New Jersey Septic Tank Pumping Helps Reduce the Risk of Well Water Contamination

For homeowners in New Jersey, septic system maintenance should be as much a part of normal home maintenance as raking leaves in the fall. Unfortunately, while it is obvious when your lawn needs a cleanup, it’s much easier to forget about septic tank pumping. As a result, not all NJ septic system owners have their tank pumped as often as they should. Unlike other household tasks, if septic service is neglected there can be serious repercussions, especially for those who also have well water on their property.

Health Risks of Neglecting Septic Maintenance in New Jersey

It is important to note that having both a septic system and well water at your home is perfectly safe, as long as both systems are properly maintained. However, when regular septic tank pumping is not performed, well water contamination can occur. Contamination not only changes the look and taste of your water but it can also be a source of disease and other health problems. These issues can range from stomach problems to cholera and hepatitis A. If an elderly person, pregnant woman or small child lives in your home, this is especially dangerous since they are more susceptible to disease. Water contaminated by a septic system can cause a potentially fatal condition unique to infants called methemoglobinemia, also known as blue baby syndrome. This condition hinders the bloods ability to carry oxygen, causing the skin to take on bluish tint and earning the disease its unpleasant nickname.

How Septic Systems Contaminate Wells

The health problems are serious but they can easily be avoided. The best way to prevent this kind of contamination is to make sure you have routine septic pumping services performed by Russell Reid. For most people, this means getting serviced once every two to five years based on the size of your tank and how many people are using it regularly. If a septic tank is not pumped out often enough, solids collect and take up space in the tank. When the tank is too full, wastewater is forced out before solids in the water have time to settle to the bottom. When wastewater is pushed out before it is fully filtered, the solids that remain in the water are pushed out with it. This can cause contamination in two ways. The water and waste particles can find their way directly into the well or it can clog the drain field. Drain fields are not meant to handle particles in water over a certain size, and if materials that are too large get in there, it will clog. Every time water goes through the drain field in the future, it will wash over these waste solids, contaminating water headed for the well. It is also possible that the wastewater and the stowaway waste particles may find a way to enter the well directly.

When a well and septic system are both present, regular septic tank maintenance is crucial and the consequences from putting off this task can be harmful. However, if you are diligent about regular septic pumping there is no reason your septic and well can’t coexist for many years without any negative effects on you or your family. If you are unsure of how often our tank should be pumped, feel free to contact us for more information.

New Grease Trap Maintenance Plans Are Here!

We are pleased to announce the availability of grease trap maintenance plans for our restaurant and food service customers. The new maintenance plans offer a great way to control costs while keeping maintenance on track.

Three plans are available for exterior grease traps and range from cost effective to comprehensive, depending on the level of protection desired. They include scheduled grease trap cleaning and inspection as well as scheduled jetting services. The higher level plans include bio treatment as well as an overflow guarantee. Customers pay only one low price each month and are able to stabilize maintenance costs for their grease trap and drain lines.

Contact us for more information or for an enrollment form today!