Russell Reid Converts Rutgers Food Waste to Renewable Energy

Russell Reid has been recognized on My Central Jersey News for reusing fats, grease and oils from Rutgers University Dining Halls to help curb the fuel costs and client footprint at the Joint Meeting of Union and Essex Counties Waste Water Treatment Plant in Elizabeth, New Jersey.

Representatives of Russell Reid and Joint Meeting explained how the leftover food particles and oil and waste makes its way down to the outdoor grease trap, where the separation occurs. Russell Reid technicians prevents clogs by sucking out the fat and waste from the trap, so that the system operates well. At the Waste Water Treatment Plant at Union and Essex, the water gets discharged off the truck and through the facility. The fats, oil and grease material serves as a food source to various microorganisms that produce methane gas, which is used as a fuel in the cogeneration process for electricity and heating.

You can also watch the video on My Central Jersey here.

It’s Easy to Digest Sustainability with Russell Reid

The Russell Reid Company prides itself on being a company with its goals set toward the future. Our projects, services, and team keep sustainability in mind, particularly in our work with grease trap pumping. We don’t blame restaurant owners for not thinking twice about where their grease goes after it’s out of the tank. But the truth is that the greasy leftovers from your favorite guilty pleasure are just at the beginning of its life –– and purpose.

In a typical month, the team at Russell Reid can deliver up to 300,000 gallons of grease trap waste, or what is known as FOG (fats, oils, & grease) to our partners at the Joint Meeting of Essex and Union Counties (JMEUC), a Publicly Owned Wastewater Treatment Works (POTW). It is received in the Scum Collection System and later pumped into an anaerobic digester that uses the grease as a food source for the organisms that live inside. These organisms use the process of anaerobic digestion to metabolize and therefore breakdown the lipids and proteins that makeup the grease. The waste products of this digestion include carbon dioxide, hydrogen sulfide, methane, and water vapor.

While those gases are waste for the organisms that break down the grease, they are actually vital resources to the process that unfolds at Joint Meeting. The gas from the digester is cooled, and the methane is separated from the rest of the byproducts so it can be used as fuel for generators. Using solely the methane produced from the grease that Russell Reid pumps, a.k.a. the food scraps from your favorite restaurants, JMEUC is able to sustain 75% of their electrical demand.

The chain of sustainability doesn’t stop there though –– the waste heat given off during the process is used to heat water in a boiler system for both comfort and the heating of the digestion process itself. Through the grease delivered by Russell Reid from our grease trap service, the diets of anaerobic organisms, and the innovation of our partners at POTW, JMEUC is nearing a closed system of energy conversions.

So go ahead, eat out for dinner tonight! The leftovers will live on as a meal for some other living thing, and help lead us down a path of sustainable recycling and energy consumption!

Planning a Party this Summer? Russell Reid Can Help Ensure Things Go Smoothly!

Even though the weather in the Tri-State area hasn’t been picture perfect this spring, Mid-May means that we at Mr. John and Russell Reid have one thing on our minds: Summer. Once these clouds clear up, some sunshine calls for celebration. May and June are the perfect time for outdoor summer parties, and while you and your guests are celebrating Memorial Day, a graduation, or a just indulging in a reason to have some fun, we’re your one-stop shop for the party details that are a little less fun to plan.

While you choose your color scheme and decor, Russell Reid will provide you with the services you need to make sure everything runs smoothly. You may not choose to make small talk about it with the guests, but the truth is that everyone needs a place to go.

Does your home run on a septic system? If you’re suddenly expecting all of your daughter’s high school graduating class over for a party, the last thing anyone would want to handle on their special day is a septic emergency. Russell Reid offers pumping service to ensure your system is up to capacity for the grads!

Should you choose to close the doors to your home’s bathrooms, our sister company Mr. John has a wide variety of portable toilets and deluxe trailers for you to provide for your guests instead.

Whatever your reason for celebration, the Russell Reid Company wants to be there to provide you with reliable, efficient, and clean service. Let’s kick off summer together!

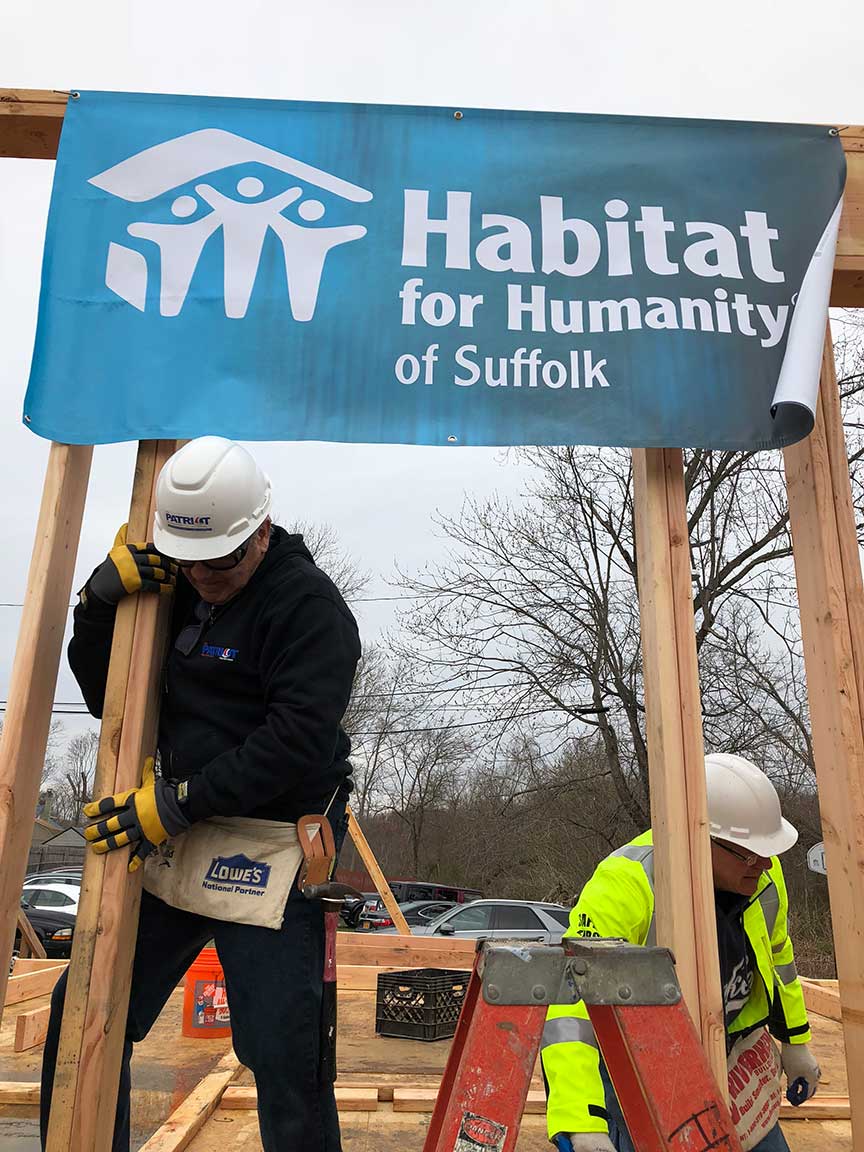

President Gary Weiner Steps On-site with Habitat for Humanity

Kudos to our sister company, Mr. John, for working so closely with Habitat for Humanity over the past few years. This past month, Habitat for Humanity Suffolk County celebrated its 30th anniversary by having CEOs from across Long Island participate in building two homes.

Among the participants was Gary Weiner, President of Mr. John and Russell Reid and active donor to the non-profit. "I thought it was an opportune time to get out and pitch in and actually do the work. Rather than just making a donation in kind, it’s where the rubber hits the road, swing the hammer, bang some nails, and build a house" Weiner said.

There seems to be something special about getting out of the office to participate in real work that makes a difference in the community. Habitat for Humanity has built over 190 homes in the past 30 years, providing affordable homeownership or families in need.

To read the full article on FiOS1News, click here.

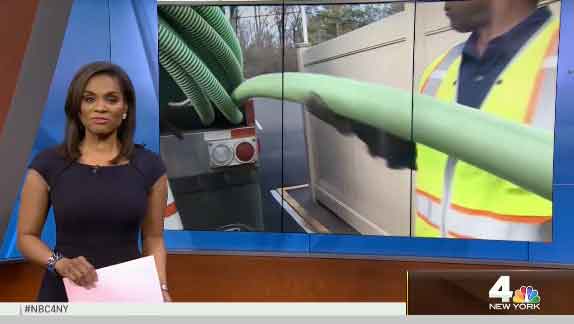

An Unusual Approach to Generating Electricity

In early April, Russell Reid was recognized on NBC New York news as one of the leading waste management companies to be generating electricity in truly innovative way. It turns out leftover fat, oil and grease from restaurant food remains may not be so useless after all.

Leftover restaurant waste turns into a layer of scum that eventually goes down the drain and into grease traps. However, there are only a few companies that pump out the grease and then bring it into a wastewater plant to create electricity. At the Joint Meeting of Essex & Union County Wastewater Treatment Plant, the grease goes into a closed digester tank to make a cleaner methane gas. With this process, we are using less oil, less coal and an overall smaller carbon footprint. This methane gas provides three-fourths of the plant’s electricity, saves about one million dollars per year, and simultaneously helps restaurants become more environmentally sustainable.

Check out the video segment below to watch the full clip:

You can also watch the video on NBC NY here.

Our Fleet is Expanding

We are very excited to announce that our convoy of vehicles will be growing, due to our recent purchase of four fantastic Presvac Vacuum Tank trucks. One of these trucks was showcased at the 2018 Water & Wastewater Equipment, Treatment & Transport Show in Indianapolis this past February. This show, also known by its initials WWETT, is the leading trade show for wastewater and environmental service worldwide.

When Waste Advantage Magazine reached out to our president, Gary Weiner, for a statement, he announced that “these trucks will enhance our operations and make us better able to serve our customers. He also added that “we are constantly upgrading our fleet to offer the best service and reliability for our customers in New York, New Jersey, and greater Philadelphia. We can’t wait to get these trucks on the road.”

These new vehicles are completely state of the art and will begin to streamline our efforts to provide our customers with the best service possible.

We would also like to offer our gratitude to the New Jersey companies who helped supply us with these trucks. The models, themselves, were supplied by Hunter Jersey Peterbilt in nearby Clarksburg, while the Presvac units were supplied by Vacuum Sales, Inc. in Lindenwold.

You will be seeing these new trucks out on the road very soon! Be on the lookout for them!

For the full story, see here:

Avoid Septic System Problems During Your Family Gathering This Summer

When planning for a gathering at your home, it is wise to include plans to prepare your septic system to make sure you don’t have any problems during your event. Russell Reid recommends following the few simple tips below to help ease the burden on your septic system during times of heavy use.

Arrange for a septic tank pumping prior to the event. Heavy volume of wastewater over a short period of time can over saturate the drain field and cause a mess in your yard or backup in to your home. Performing septic tank maintenance right before the event will create added capacity which will be able to handle more volume.

Ensure that your septic system is functioning properly before the event. You may not notice a problem during regular or modest use, but the additional volume of wastewater over a short period of time can cause an already impaired system to fail. A qualified and properly trained Russell Reid Service Technician will be able to give you an accurate overview of the condition of your septic system during septic tank service.

Make sure your drain lines are clear. If the lines are already partially clogged, they may become overloaded very quickly when faced with an above average surge of wastewater and solids. Your Russell Reid Service Technician will check the flow of water from your home to your tank to alert you to any potential problems. This is one of the items evaluated during our exclusive Russell Reid 10 Point Service Check included free with every septic tank pump out.

Make sure your guests know not to flush any improper material such as diapers or sanitary napkins down the toilet. Keep a garbage can near the toilet and post signs if needed.

Consider the use of portable facilities, such as portable toilets or portable hand sinks. Well-placed temporary restrooms and other amenities are more accessible and you will have less traffic going through your home to use the permanent facilities.

Proper maintenance and following a few common sense guidelines is all that is needed to keep a septic system functioning properly for many years to come. In the long run, the cost of a little preventive maintenance is well worth it the investment to avoid the potential for backups and septic system repairs or replacement.

Russell Reid Takes on the Manasquan River Intake Pump Station Sediment Removal Project

In August of 2013, Russell Reid executed the Manasquan River Pump Station Sediment Removal Project in Wall, New Jersey. We dedicated a team of six (6) Field Service Technicians, along with six (6) Service Vehicles to complete the project, which took a total of four (4) days to complete (August 20th through August 23rd).

The Manasquan River Pump Station Sediment Removal Project required us to remove river sediment from the Manasquan River intake pumping station. We used two (2) of our Combination Jet-Vac trucks, two (2) Vacuum Containers, along with Confined Space Entry to execute the service. The sediment that was removed from the intake station was then managed on site in a contained area designated by the customer

Russell Reid is committed to providing the best customer service experience our industry has to offer. In order to achieve this goal, we created a detailed project plan for our Field Service Technicians and Project Management Team prior to the start of the project. The first step was to perform a site visit which allowed us to figure out the most efficient way to complete the work. After reviewing the scope of work and the lay of the land, we decided to load-in and set up all the equipment we would need to complete the job before the work actually started. This process included leaving some of the trucks onsite, having a truck available at all times to refuel the onsite equipment and having all the equipment (hose, lighting, rope, confined space entry gear, etc.) readily available to perform the service as efficiently as possible. This initial planning allowed Russell Reid to perform the work in a well-organized, efficient manner.

Despite our extensive preparation, our Service Technicians did face some obstacles as the job progressed. One of the obstacles involved water leaking into the tank under the tarps which resulted in filling up the Vacuum Containers with more liquid than solids. In order to resolve this issue, the customer had to reset the pump to evacuate the water coming in from under the tarps. In addition, Russell Reid cleaned the solids from the wall which allowed the water to run through underneath to where the hydraulic pump was set (which was deeper than the floor we were cleaning), allowing the pump to remove the water. We also evacuated piles of sand which slowed down the process of removing the sediment. Not only is vacuuming sand more time consuming, but the distance in which we were vacuuming the sediment out was also very extensive (over 200 feet).

A considerable amount of time and effort was put into the project and the Russell Reid Company was pleased with the overall outcome. Regardless of the hiccups the Field Service Technicians encountered, the technicians were well prepared and were able to overcome the obstacles. Everyone involved in the project contributed to the company’s success and our customer was extremely impressed in our ability to prepare for the job, execute our plan, and perform the service in a timely manner.

The Manasquan River Pump Station Sediment Removal Project is a testament to the way the Russell Reid Company continuously provides the best service in the industry. We take pride in our ability to get the work done the right way and the way we conduct ourselves as a company. Our goal is to maintain our good customer relationships and continue to build more in the future.

Russell Reid is available for serve our customers 24 Hours: 7 Days a Week. Please feel free to reference our website or call us at (800) 356-4468.

Mr. John and Russell Reid Provide Portable Toilets and Wastewater Pumping to Those Affected by Hurricane Sandy

Are fall hurricanes becoming a trend in the Northeast? It sure seems so after the damage of Irene in 2011 and the destruction, devastation, and complete disaster of Sandy in 2012. With the impact Irene had on the tri-state area last year, the Mr. John and Russell Reid companies did not take the media advisories lightly. The company believed this storm was going to be more severe, which meant their response to storm related requests for portable toilets and wastewater services would be even more demanding.

As Hurricane Sandy quickly approached the Northeast gaining momentum, the company began planning and preparing for any and all emergency calls. Some of the preparation included checking inventory of portable restrooms and portable showers in anticipation of emergency deliveries, gathering fuel for standby generators and setting up temporary power distributions. They checked the computer backup systems to make sure nothing would be lost, set up a call chain for cell phones, and confirmed e-mail addresses. Lastly, the company preloaded all of their portable toilet delivery trailers with clean and ready to go portable toilets in anticipation of responding to calls for emergency relief services.

On Sunday, October 28th, the tri-state area slowly began to shut down. All mass transit stopped running after 7PM and all major bridges, tunnels, and highways were closed due to risks of high winds until further notice. As the fear of the storm grew, offices, shopping centers, local stores, and gas stations began closing for the night and following day as well. The Mr. John and Russell Reid Company closed all their offices on Monday, October 29th for the safety of their workers. Little did they know, the heart of the storm had yet to hit the tri-state area. Monday night people began losing power, trees were falling down, massive flooding was occurring, and all the sewage lines were beginning to back up. At this point, the response for both the Mr. John and Russell Reid Company’s was very important. Luckily, they had a plan of action and were ready to perform in order to provide temporary restrooms and wastewater pumping services.

Tuesday morning was a difficult time for many people, including the workers of the Mr. John and Russell Reid Companies.The electricity in all the offices was out, and emergency calls for portable toilets and waste removal services started to come in. Fortunately, the company was very prepared and ready to respond. As some people were unable to get to work due to damage from the storm, those who made it rose to the occasion. The field service technicians worked hard to fulfill storm related requests despite the dreadful circumstances. The determination and dedication to serving their customers, especially in times of an emergency, is a testament to the quality of work the Mr. John and Russell Reid Companies provide.

Some of the emergency calls the Mr. John and Russell Reid Company received included working closely with the Port Authority to remove storm water from the Holland Tunnel. This required working through the night and weekend to pump all excess water in order to reopen the tunnel to the public. Russell Reid also helped industrial waste water users to manage their output while sewer treatment plants were off line. They were also cleaning storm and sanitary sewer systems to allow normal flows. In addition, the extreme flooding that occurred all over the coast line created a huge demand for cleaning out catch basins and storm drains. Everything was backed up due to the massive amount of sand in the streets. There were also hundreds of temporary restrooms delivered throughoutNew Jersey and NY in response to power outages, destroyed homes, and lack of running water.

Hurricane Sandy has had a huge impact on the tri-state area, especially hard hit areas near the shorelines.Most people were without power for days, but others have lost homes, belongings, pets, cars, etc. The Mr. John and Russell Reid Companies are pleased to have been able to respond to the emergency calls and continue to provide portable toilet and waste related services as the area attempts to get back to normal. Thanks to the hard-working, dedicated staff that was able and willing to respond to customers’ needs regardless of the challenges and issues that rose due to the effects of Hurricane Sandy. The effective plan of emergency action has allowed the company to once again provide quality services in times of crisis.

The Secret Underground – How Wastewater Management Systems Help Protect our Environment

Most of us do not give a second thought to what happens to waste after we get rid of it. ‘Out of sight, out mind’ as they say. The truth is; every piece of discarded trash or debris, whether tossed, flushed or even thrown in the garbage, must be dealt with in some way in order to protect our environment.

You may not know that there are many underground systems in place, silently working to treat or pretreat our waste. These systems range from small tanks to large multi chamber facilities designed to reduce the most amount of pollutants. Some are used to pretreat waste prior to sending it on to municipal waste treatment and others are designed to work independently of the municipal system, performing all phases of treatment on site.

Septic tanks and cesspools may be the most commonly known onsite wastewater management system. They operate independently of the municipal system and employ a natural method of wastewater treatment. Settling and natural breakdown by bacteria is aided by occasional septic pumping to remove solids and the clean water is released back in to the environment. However, without occasional septic system cleaning to remove the solids, this material can be forced in to the drainfield, polluting the land and clogging the soil so that the system may fail over time.

Grease is the most common cause of sewer backups and can clog up municipal wastewater treatment facilities. To help prevent this, most restaurants and food processing establishments have grease traps to help filter grease from the water before it enters the municipal sewer system. Grease traps also use a natural method which includes cooling and separation. Regular grease trap pumping helps remove the solid material to keep it from building up and entering the municipal system or causing a clog or back up. Some municipalities even regulate grease trap maintenance in order to reduce the amount of grease entering and clogging their systems.

In order to combat pollution and protect our water quality, the EPA now mandates that any new development or site that is being expanded, either larger than one acre in size or close to a waterway, must have a stormwater maintenance plan in action. These plans involve having systems on site to pretreat wastewater. Some of these systems treat wastewater that is generated during a manufacturing process or other facility operations. Others are designed to filter out garbage and debris from stormwater to prevent it from entering our waterways.

The old traditional types of stormwater treatment are no longer sufficient and do not remove enough pollutants. Newer treatment systems are designed to remove not only garbage and large particles, but also filter out fine particles such as grease, oil, chemicals and other contaminants. Good examples of these are the StormFilter and Vortechs systems, which are manufactured by Contech Construction Products, Inc.

The StormFilter system is an underground system which collects and treats wastewater using a system of filters. The tank collects large debris such as garbage and the water flows through the filter system which collects smaller particles as well as grease, oil and other pollutants. The Votechs system also collects and treats wastewater prior to discharge, but uses a swirl chamber which separates the pollutants and stores the waste for removal. Both systems require maintenance in order for them to continue to function reliably. Maintenance schedules vary depending on the amount of waste being treated.

In this time of greater environmental concern, more and more people are becoming aware of their impact on the environment. Hopefully, with greater awareness will come more responsibility. Meanwhile, Russell Reid will continue to travel the region and service the silent underground, one stop at a time, in our never ending journey to do our part to help protect the environment.